Tomatoes Overview

Tomatoes are grown in abundance both in the summer and winter seasons in India. The crop grown in the winter is of superior quality because they contain more total solids. The tomato paste retains all of the flavour, sweetness, and nutrients in the fresh fruits. The tomato processing industry in India is equipped with state of the art manufacturing facilities and advanced technology.

Around 80% of the tomatoes are consumed fresh and 20% are employed in the processing to make tomato paste, puree, ketchup, pickles, juices and sauces. Tomato paste is a smooth thick substance manufactured by processing fresh and ripened tomatoes. Tomato paste is a raw material for manufacturing tomato processed products. The sauce and ketchup sector is the major user of tomato paste.

Tomato puree is used as a substitute of fresh tomato in cooking. Ketchup is a sweeter and diluted version of puree(Pulp). Tomato sauce tastes sweet and sour. Both sauce and ketchup are consumed with food and snacks.

The demand for tomato processing usually arises from a need to preserve the product for home use (inclusion in stews, soups, curries etc.) out of season or to add value for extra income. Traditionally, the most important methods used are concentration (to a paste or purée) and drying either fruit pieces or to a powder.

Is Tomato Processing Business Profitable?

Manufacturing tomato sauce is a profitable business venture if started with proper planning and presentation. India, being one of the largest producers of tomatoes provides a great market for the tomato sauce manufacturing as homemade tomato sauces are gaining great demand from the market. Their unmatched taste and quality are helping them stand apart.

With an annual growth of over 20% per annum, the demand for tomato sauce is getting huge in India which is expected to rise more in times to come. It can be used along with snacks to coloring and seasoning in restaurants. The eating culture of Indian people has certainly given rise to the use of tomato sauce extensively.

Basically, tomato processing includes different types of value-added product manufacturing. These are tomato juice, puree, sauce, ketchup, and tomato pulp. Basically, tomato juice and pulp have industrial use along with domestic consumption.

Due to increasing standards of living in the cities and the rapid urbanization in the rural areas, the demand for ready-to-eat items is also growing. Additionally, the changing food habits including the growing fast food industry have created a boost in the demand for processed tomato items.

The tomato processing industry is huge. The only ketchup and sauce market in India is pegged at Rs. 1,000 crore and growing at around 20% year on year. There is a big market for processed tomato products.

The market scenario has revealed a positive indication for the specially packed tomato sauce in local as well as the outside markets. Rapid urbanization has increased the use of processed tomato products. Another aspect is modern packaging technology such as Multi-layer- Flexible plastic packaging, Tetrapack, and Brick packing has made it possible to distribute tomato products to wide, distant, and remote areas.

It allows storing the products at room temperature for a period of more than 4 months. It has also increased the shelf life of these products, which has contributed substantially to boosting the demand for tomato products in India and Globally.

At present, the market of ketchup/puree, specially in the urban areas, is dominated by brands likes MAGGI and KISSAN. Some Medium and Small Companies are also engaged in its production.

Recently, there was a steady rise in production due to the entry of multinationals with better market infrastructure and sales promotion campaigns. With high fluctuation in market prices of fresh tomatoes in the urban market, there are good prospects for tomato juice, and tomato puree in place of fresh tomatoes in household sector.

Besides the boom in the food service sector including fast food chain, has widened the demand potential for tomato ketchup and soups.

Processed tomato products have good export potential, especially in the Middle East. Many units are operating in the small-scale sector in the country. Initiating a small-scale tomato processing unit, focusing on a single product is a financially viable investment opportunity

8 steps to follow to start a profitable Tomato Processing business

1. Create a Business Plan

A business plan is the key to success for any business. The required capital for starting the business is a bit high as machineries are themselves expensive. A well-crafted business plan is required to speak of the operational process of the business in a profitable manner. Legal guidelines will be strict and strong which has to be followed according to the law. The three steps in a business plan can include:

- Select your Niche

There are plenty of different types of tomato processed items you can produce from the tomato processing unit. A few popular items can be tomato paste, tomato ketchup, tomato sauce, tomato soup, tomato pulp, etc. Selecting the right niche is critical to your success in this business. - Do some Market Research

If you are starting with less capital, the immediate market you must concentrate on is your local community. Research the local market and analyze the demand of local customers. Go to retail markets and find out what kind of items is selling most and the taste of your local market. - Learn the Tomato Processing Production Process

It is best if you can meet existing tomato processing manufacturers and visit their units. This will give you a fair idea of the production process and various machinery required to produce tomato-processed items. Also, try to learn the manufacturing process in detail when you talk to equipment manufacturers.

2. Choose a Location for Tomato Processing Business

Find a location, where distribution cost is low. The location should be nearer to the suppliers who will supply raw materials to your plant. It also should not be too far from the immediate market where you will be supplying finished goods.

Choosing a suitable location for your tomato processing plant is a very important factor that can determine how successful and profitable the business grows. The factors you need to consider when searching for a location to build your tomato processing plant are nearness to tomato farms/ plantations, nearness to source of cheap labor, as well as proximity to the market. You might also position your tomato processing plant to be close to the Seaport or Rail station so as to cut transportation cost especially when you intend to go into exportation of your processed tomato products.

3. Name your Tomato Processing Business

Select a name that people can relate to your tomato processing company. Do not forget to check the availability of a similar domain name to the company name. This helps you in creating a website similar to the company name.

4. Make the Business Legally Compliant

In starting any tomato processing business you must obtain the following registration and license from the concerned department.

-

- Register your firm with ROC as per the management liability and mode of operation.

- Obtain Trade License from local Authority

- Open a current account for a cash transaction

- Obtain Udyog Aadhaar MSME registration.

- Obtain FSSAI licence

- Apply for GST registration number

- Obtain, BIS certification. The agency offers different standardization for different tomato processed products. Such as for Tomato Juice IS 3881:1966, Tomato Ketchup IS 3882:1966, and Tomato Puree IS 3883:1966..

This type of unit does not attract pollution to the environment. However, material waste (skin, seeds, etc.) is the main effluents for which the provision of treatment is there. It is recommended to have NOC from the state Pollution Control Department.

Choose the right form of your business according to the ownership and investment pattern. It is advisable to consult with a small business expert to understand the permission and licensing issues. We should also not forget to get your manufacturing unit insured.

5. Machine & Equipment for Tomato Processing Business

The Tomato Processing Plant is basically composed of:

-

- Tomato Reception, Washing, Sorting & Inspection Section

- Pulp Section

- Concentrating section

- Packaging.

6. Cost of Starting Tomato Processing Business

The actual cost of the project may deviate from a change of any of the assumptions. To start this business, a total of Rs 7.82 lakh is needed. In which, you will have to invest Rs 1.95 lakh from yourself. If you need financial assistance, the government provides Mudra loans to start such businesses.. So, the rest of the money you can arrange by availing of a loan under the Mudra Loan Scheme.

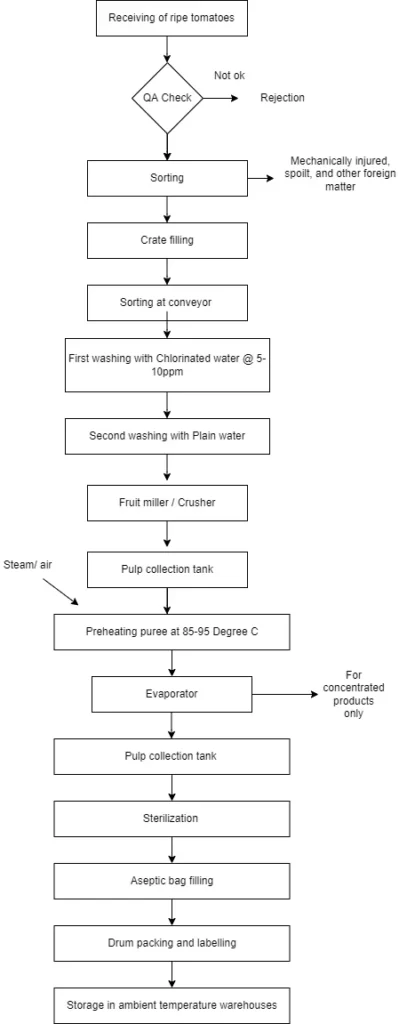

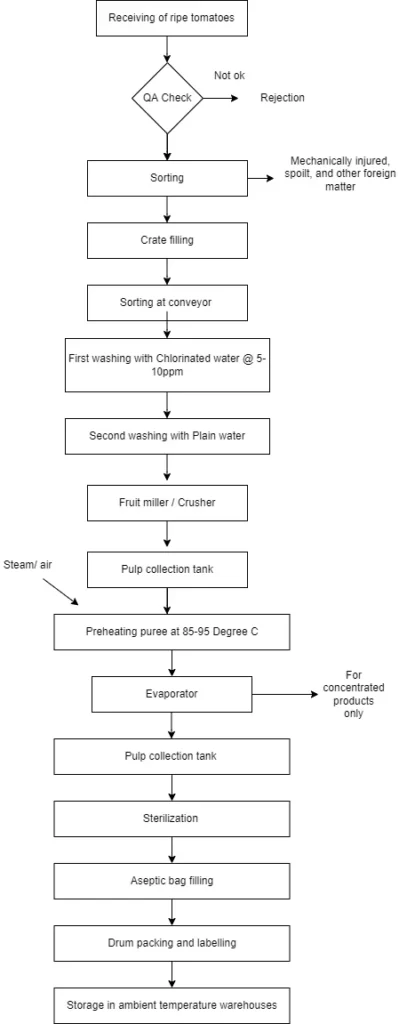

7. Tomato Manufacturing Process

The ripened tomatoes are unloaded in the factory and it undergoes the first stage of quality control. The fruits are then sorted to remove mechanically injured or spoiled fruits. The fruits are unloaded and filled in the crates. The tomato paste processing begins by washing tomatoes with chlorinated water at 5-10ppm and then with plain water to remove dust particles.

The tomatoes are crushed in the fruit miller and the pulp is collected in the pulp storage tank. The puree is preheated at 85-95 Degree Celsius and refined to remove seed/ tomato waste. The product is passed through the evaporator to remove the water content. The tomato paste is then passed through a strainer and metal detector to remove impurities. Eventually, the product is sterilized and filled in aseptic bags. The tomato paste with aseptic bags is packed in MS drums and stored in the warehouses. The tomato paste is further processed into ketchup, sauce, and other processed tomato products.

- Tomato Products Manufacturing

1. Tomato Processing for Juice

First of all, you have to procure fully ripe well-developed color tomatoes for making juice. Then, wash the tomatoes. After trimming and steaming, crush them in a crusher or cut them into pieces with knives. Then heat the crushed pieces in the steam jacketed kettle till they become quite soft.

Finally, pass the heated tomatoes through the pulping machine using a fine-mesh sieve to separate the juice from seeds and the skin. Keep heating to 85-90ºC and add the sugar and salt @ 1%. The hot juice is then filled in bottles, sealed immediately, processed sterilized in boiling water for about 30 minutes, and cooled.

2. Tomato Processing For Ketchup

According to the Indian standard specification for tomato ketchup, it should be prepared from sound and ripe tomatoes with more than 25% weight of soluble solids. The juice obtained as above is concentrated with spices, salt, sugar, etc. The spices like cloves, cardamom, pepper, cinnamon, other ingredients, etc. are tied loosely in a muslin cloth and placed in boiling juice in steam jacketed kettle. The sugar, salt, vinegar or acetic acid, etc. are added later on.

3. Tomato Processing For Paste & Pulp

To prepare tomato paste and pulp, the juice is further concentrated under vacuum to around 9% to 12% solids. Also, you can prepare tomato powder using different technologies depending upon the end use of the product. Additionally, you can source the tomato processing technology from any reputed Government research institutes.

4. Tomato Processing For Puree

First of all, obtain the juice obtained as above. Then, concentrate it under vacuum to about 9% to 12% total solids so as to get tomato puree. Finally, fill the product in bottles. Seal the bottles with crown cork and process in boiling water for 30 min. and cool.

5. Tomato Processing For Sauce

For preparing sauce, you will need to concentrate the juice under a vacuum and controlled temperature. In addition, you have to add salt, sugar, vinegar, spices, onion, etc., as per requirement. Then, boil this mixture under vacuum till it contains a minimum of 12% tomato solids and 28% total solids. Then pass the sauce through a sieve to remove fibrous and other materials. Finally, cool the material and add the preservative prior to sending it for packing.

8. Promote your Products

Promotion and marketing are the musts to get overall success in this business. Additionally, you must pay attention to the packaging. There are various packaging styles for processed tomato products. You could choose to use bottles, sachet or even plastics. Whichever choice you choose for any of your products, just ensure that the packing is appealing and unique.

First of all, try to hit the local consumers. And a well-penetrated distribution channel is the best option to capture the local retail market.

Additionally, supermarkets and malls are great places to promote your product. If you are starting tomato processing on a large scale, you can consider export also.

Nowadays building a website is a must. If you are starting with a shoestring budget, no need for hiring agencies to create your website. You can build your own. It won’t take more than 30 minutes even you are an absolute newbie in technically creating a website.

The fact that people eat tomato all over the world makes it easier for you to sell your processed tomato products beyond the shores of your country. You can be rest assured that there are international markets waiting for you to explore.

The truth is that if your products are good and of international standards, then with a little push; you can easily break into the global market. People export processed tomato products to every nook and cranny of the world without restrictions.

-

Tomato Processing Quality Control

Compliance with the Fruit Products Order, 1955 is mandatory for tomato processing. The tomato products should conform to specifications laid down in FPO. The FPO specifications are as follows:

-

- First of all, Tomato Juice: 5% total solids.

- Tomato Puree: 9% total solids and Sodium Benzoate 250 ppm

- Tomato Ketchup: 25% total solids. Acidity: 1.0% Sodium Benzoate: 750 ppm

- You may also adopt HACCP and ISO 9000 certification for tomato processing plants.