Soft Drinks Overview

- Carbonated soft drinks are generally sweet, non-alcoholic effervescent beverages. Some of the most well-known examples of carbonated soft drinks are Coca-Cola, Mountain Dew, Sprite, etc.

- Soft drinks are beverages produced from (mineral) water with sugar or sweeteners. Generally, soft drinks contain carbon dioxide. The carbon dioxide has three functions:

-

- It provides a cooling sensation: through the evaporation of the gas heat is extracted from the tongue.

- It lowers the degree of acidity (pH 2.2 – 3.6), slowing down the growth of microorganism. However, other preservatives may be added in addition.

- It poisons the air that is possibly present above the soft drink, making it impossible for fungi to grow, due to the lack of oxygen.

- Water, sugar, acid, colouring and flavouring agents are the major raw material used in soft drink production process and carbon dioxide is also used in it. Carbon dioxide act as an inert, non-toxic, relatively inexpensive and easy to liquefy. Ingredients and flavours get differ according to the type of the product.

- Soft drinks include all drinks made from water or mineral water, sugar, aromas, and essences, and usually contain carbon dioxide. Other beverage products such as flavored water, sports and energy drinks, and ice teas use a similar manufacturing process.

- The first soft drinks appeared in the 19th century, shortly after the process for manufacturing artificial sparkling mineral water was developed. In the 20th century, these sweet, fizzy, refreshing drinks offered an alternative to the increasingly high consumption of alcoholic beverages.

- Today, soft drink manufacturers are adapting to consumers demands for more novel flavor profiles and more healthy choices. The industry is ripe for innovation, with customers on the lookout for more premium soft drink beverages with interesting flavor combinations. So setting up a Carbonated soft drink plant is a highly profitable business for new entrepreneurs.

CSD (Carbonated Soft Drink): Traditional fizzy drinks, sodas or pop. The product needs to be carbonated. Excludes carbonated energy drinks or sports drinks.

Energy Drinks: Beverages that claim to awaken or provide alertness. Beverages that promote alertness and are marketed as a soft drink with added benefits.

Sports Drinks: Beverages that claim to rehydrate/replenish, as well as restore minerals, sugar and other nutrients lost during exercise.

Is Soft Drink Processing Business Profitable?

- The cost of soft drinks production is very low while the demand is surplus everywhere. Soft drinks can make a profit at any price, it is the largest and most profitable market in the larger beverage industry.

- The most popular soft drink glasses range from ₹15 to ₹20, with 50 to 60% profit margins. If your cold drink agency can sell 300 glasses of ₹15 per day, you can make between ₹4,500 and ₹5,000 per month, which is around ₹1,20,000 profit.

- The profit margin on cold drinks ranges from 10% to 20%.

- India’s population is growing, as is the economy, and as a result, so is the need for food and beverages. The beverage industry in India has a major potential for growth, thus involving in this business would be a fruitful venture.

Soft Drink Market Potential

- Pepsico is the biggest soft drink company in India. As per the company, the Indian soft drink market might continue its “robust growth trajectory” as annual per-capita bottle consumption is expected to grow very fast.

- There are some of the reasons for this growth forecast. These are the growing middle class, rising affordability, and urbanization, and rural electrification besides continued innovations towards product packaging and sizing.

- India exports soft drinks and is the second-largest exporter in the world. It has created a good international market and also established bottling plants in New York, Kuwait, Oman, UAE, Malaysia, Sharjah, etc.

- The consumption has increased by 17 % per annum and has tremendous prospects for an entrepreneur.

- The non-alcoholic beverage sector in India like squashes, fruit juices, soft drinks, aerated waters, mineral waters, and syrups has grown significantly in recent years.

Eight steps to follow to start a profitable Soft Drink Processing Business

-

Create a Business Plan

- The most crucial component of this business is creating a foolproof business strategy. To do so, you must first perform market research. Recognize the market’s needs and then decide on the specific product you’d like to make.

- Determine how much money you’ll need to get started. Both fixed and variable expenses must be calculated. Create a strategic collaboration with the cold drink dealers in your manufacturing area and develop a marketing and distribution plan for the product.

2. Choose a Location for Soft Drink Processing Factory

- Find a location, where distribution cost is low. The location should be nearer to the suppliers who will supply raw materials to your plant. It also should not be too far from the immediate market where you will be supplying finished goods.

3. Name your Soft Drink Processing Business

- Select a name that people can relate to your Soft Drink processing company. Do not forget to check the availability of a similar domain name to the company name. This helps you in creating a website similar to the company name.

4. Make the Business Legally Compliant

- In starting any Soft Drink processing business you must obtain the following registration and license from the concerned department.

- Register your firm with ROC as per the management liability and mode of operation.

- Obtain Trade License from local Authority

- Open a current account for a cash transaction

- Obtain Udyog Aadhaar MSME registration.

- Obtain FSSAI license

- Apply for GST registration number.

5. Machine & Equipment for Soft Drink Processing

The Soft Drink Processing Plant is basically composed of :

-

- Sugar Syrup Preparation Unit

- Pulp Unloading Section

- Beverage Blending Section

- Sterilization Section

- Filling section

- Clean–In–Place System.

6. Cost of Starting Soft Drink Manufacturing Plant

It is without saying, the cost and investment will mainly depend on the scale of business and production output.

The cost of a carbonated soft drink automated plant cost with 1 pair of machines will range from Rs. 20 lacs to Rs. 50 lacs depending on the production capacity. The cost will come down to around 10-15 lacs with a semi-automatic machine.

In addition, you need to invest in land, inventories, legal costs, manpower costs, and 3 months of working capital. Total investment in the range of Rs 30 lacs to Rs. 1 Crore will be required to start a soft drink manufacturing plant in India.

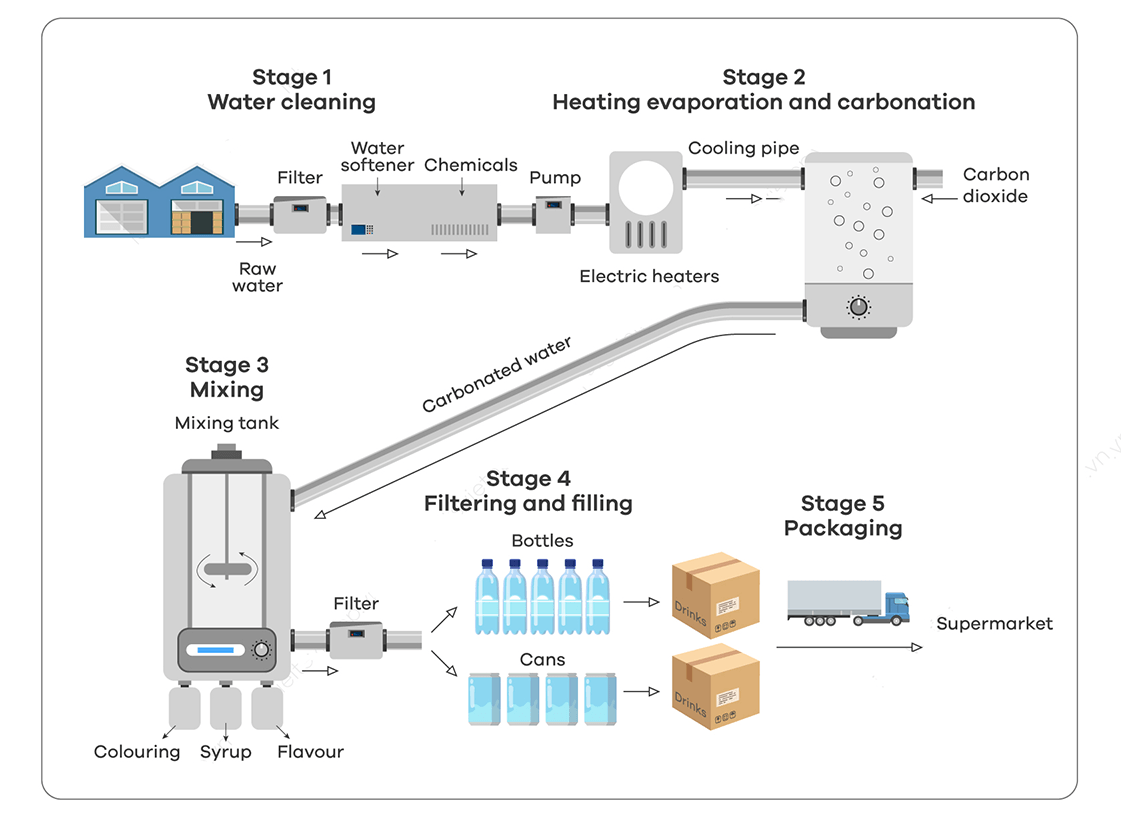

7. Soft Drink Manufacturing Process

Steps involved in production process:

-

- Raw material preparation

- Clarifying the water

- Filtering, sterilizing, and de-chlorinating the water

- Mixing the ingredients

- Carbonating the beverage

- Filling and packaging

- Quality Control

- Broadly, you can produce soft drinks in two ways. These are premix and post-mix methods.

- In the premix method, you will need to combine all the ingredients with water in a vessel or mixing tank.

- In the post-mix method, you will need to add the water at last with other ingredients. This method is perfect for large-scale production.

- The final task is bottling and labeling. On the label, you must mention the company name, registration number, manufacturing date, MRP, and the class of the preservative you use.

Water, sugar, acid, colouring and flavouring agents are the major raw material used in soft drink production process and carbon dioxide is also used in it. Carbon dioxide act as an inert, non-toxic, relatively inexpensive and easy to liquefy. Ingredients and flavours get differ according to the type of the product.

Water is allowed for clarification process to remove the impurities and then, they are undergone for filtration to destroy the organic matter, and bacteria, which may degrade taste and colour. Now, the ingredients are mixed with each other and the flavours are added according to the requirement. This mixing of ingredients is known as syrup. This syrup is pumped into the dosing station and they are sterilized, by quick cooling and heating process. Then, the drink is undergone for carbonated process, were the carbonated is added to the beverage by carbonated beverage machine. Finally, the beverage is allowed for filling and packing process, were the machines automatically fills and seals the bottle and then, the bottles are packed into cartons or trays.

8. Promote your Products

- Generally, the long-term success of FMCG products depends on the successful distribution network. In addition, you will need to concentrate on tying up with the malls, supermarkets, and retail chains. Overall branding and advertising are a must in the and paneer manufacturing business.

Explore

Related Products