Fruit Juice Overview and insight on Fruit Juice Business

- Fruit juice is 100% pure juice made from the flesh of fresh fruit or from whole fruit, depending on the type used. It is not permitted to add sugars, sweeteners, preservatives, flavourings or colourings to fruit juice.

- Fruit juices are usually described as:

-

- From concentrate

- Not from concentrate

- Freshly squeezed

a) Fruit juice from concentrate

- Juice is extracted from the fruit and the water content is reduced—by evaporating off the water naturally present—in the country of origin. The concentrated juice is usually frozen and shipped to the country of use for packing. Fruit juice packers then reconstitute the juice by adding back the water.

b) Not from concentrate juice

- Juice is extracted from the fruit in the country of origin and then lightly pasteurised and frozen, chilled or aseptically transported to the country where it will be packed.

c) Freshly squeezed juice

- Juice is extracted from the fruit and used immediately.

Juice and juice products represent a very important segment of the total processed fruit industry. Juice products are being marketed as refrigerated, shelf-stable, and frozen, in a variety of packages with increased emphasis on functionality, health attributes, new flavors or blends, and in some cases fortified with vitamins and minerals. High-quality juice operations are dependent upon a source of high-quality raw material.

Most fruit juices are excellent sources of vitamin C, several are good sources of carotene and many contain moderate amounts of pyridoxine, inositol, folic acid and biotin. Fruit juice is regarded as source of energy due to their rich carbohydrate content. The organic acids present in the fruit juice plays a significant role in the maintenance of the acid-base balance in the body.

- Fruit Juice Business is possible in two ways, the first method is to sell Fresh Juice by opening its shop in a busy market and second method is by selling it in the market by processing and packaging the juice. Where the first method sets the limit for the business of entrepreneur, by adopting another method, the entrepreneur can sell his juice anywhere in India. You can also consider opening a Fresh juice Franchise In India.

- If you want to start a small-scale fruit juice production business – can be started with a small investment. The raw material of this business – fruits, is easily available across the country. It doesn’t demand complex manufacturing technology.

- There are three types of fruit juices available in the market. Fruit drinks, which have a maximum of 30% fruit content, are the highest-selling category. Fruit Juices, are 100% composed of fruit content and claim a 30% market share at present. In contrast, nectar drinks have between 25-90% fruit content but account for only about 10% of the total market. According to the specific product, you want to produce, you must select the right machinery.

- For fruit juice production, major raw materials are different types of fruits. Apart from fruits, you must procure sugar, preservatives, food colors etc.

- Packaging plays an important role in fruit juice production. Tetra pack is most popular among the consumer. Pet bottle pack is also running in the market. According to the size, you want to deliver, procure packaging consumables. In a case of pet bottles, you must arrange the labels with proper product information.

Is Fruit Juice Business Profitable?

- According to the business experts and market research, the current market size for the fresh fruit juice business in India is around 3200 crore. The market is estimated to grow at the rate of 25%-30%, owing to factors like urbanization, increasing disposable income and entry of organised players into the market. Majority of the fresh fruit juice business in India is still un-organised and dominated by roadside shops, run by sole proprietors. However, organised players have begun penetrating Tier 1 and Tier 2 cities in India by establishing fresh fruit juice chains and distribution of pre-packaged fresh fruit juices.

- Within the beverages market, packaged fruit juice is one of the fastest-growing products. It has grown at a CAGR of over 30% over the past decade. At present, the Indian packaged juices market is valued at Rs 1100 crore and is projected to grow at a CAGR of 15% over the next three years.

- The rising number of health-conscious urban consumers is giving a boost to fruit juices. Juices are healthy only when prepared hygienically. So the hygiene-conscious people are only buying packaged fruit juices for the companies that have trusted brand value in the market.

- Growing affordability and rising disposable income are also responsible for the growing demand for fruit juices in the Indian market. Last but not least, the boom in retail merchandising and eCommerce plays as major growth drivers in the fruit juice market in India. Thus, we can conclude, small, medium or large scale fruit juice production is a profitable investment opportunity for new entrepreneurs.

Setting up a Fruit Juice Manufacturing Plant – (The Groundwork for Starting Fruit Juice Business)

While setting up a fruit juice processing plant is a profitable business in India, several points should be considered to ensure it remains profitable in the long run. You can start with a specific product, or choose to setup a multi-fruit juice manufacturing plant.

The amount of investment depends on the choice you make, and your revenue depends on the size and type of plant you establish. The ideal way is to start a small-scale fruit juice processing plant to understand the market, analyze the variations in demand, and plan for expansion in the future.

The type of manufacturing technology also depends on the type and size of your processing unit. The raw materials for this business – fruits are available easily across the country, and it usually doesn’t require a complex manufacturing technology.

8 Steps to follow to start a profitable Fruit Juice Processing Business

1. Create a Business Plan

- A business plan should be made keeping in mind the expenses and earnings. By having a business plan, the entrepreneur will save himself from being in the dark or the challenges in business will already solve a solution to the difficulties as the business plan will help the entrepreneur to give information about the fluctuations in his business. A good business plan, where the entrepreneur will be informed about his financial goals, will also provide information about the size of his business.

2. Choose a Location for Fruit Juice Processing Factory

- When choosing a location, the entrepreneur has to take care of different things, even in the nearby places, how much juice is used every day and how much percent of the juice will be sold in the Target Market, also has to be analyzed. Initially, the entrepreneur should start with the low Plant Capacity so that the entrepreneur can increase his plant capacity along with the sale. While selecting the location, it is very important to keep in mind that whether the basic features like electricity, water, road, manpower exist in that location. Apart from this, the assistance and support given by the government are also to be considered.

3. Name your Fruit Juice Processing Business

- Selecting the name should be based on the points discussed previously. Make sure to keep the name simple and friendly to remember. Adding a personalized touch is always advisable, but it is easy to recall.

- Select a name for your business that is catchy and easy to remember for people. In addition to this, check whether a relevant domain name is available or not if you intend to make a website.

4. Make the Business Legally Compliant

- In order to start Fruit Juice business In India, the entrepreneur is required to get various types of registration, in which FSSAI license and GST registration is mandatory. The entrepreneur wants that he should choose one of the different business entities in the Registrar of companies. After that, get a license to deal with the local authority such as the municipality, municipal council etc.

- If the entrepreneur wants to get the benefit of various schemes introduced by the Government of India for small industries, then it can also register its business in the industrial base. Food Safety and Standards Authority of India (FSSAI) license and tax registration is mandatory to do this business.

- Apart from this, if the entrepreneur wants that his business logo and brand should not be used commercially by any other company or person then the entrepreneur should also register his Trademark. To start a fruit juice production business in India, you will need to obtain different registrations and licenses from Govt authorities. These are as follows:

- Firm registration with ROC

- Trade License from local Municipal authority

- MSME Udyog Aadhaar Registration

- FSSAI registration

- GST registration

- Compliance with the FPO act is mandatory.

Additionally, you must maintain the guidelines such as location and surroundings of the factory, sanitary and hygienic conditions of premises, personnel hygiene, portability of water, machinery & equipment with installed capacity, quality control facility & technical staff, product standards, limits for preservatives & other additives, etc.

5. Machine & Equipment for Fruit Juice Processing Business

The Fruit Juice Processing Plant is basically composed of:

-

- Reception, Washing, Sorting & Inspection Section

- Pulping, Crushing, Concentrating Section

- Sugar Syrup Preparation Section

- RTS Tubular Pasteurizing/ Homogenizing Section.

- Packaging Section.

Some of the common equipment’s which are used in the fruit juice industry are listed as below:-

-

- Fruit elevator: used to transmit fruits from low position to high position, and connect 2 adjacent procedures. Usually placed between fruit sorter and washer or after the fruit sorter.

- Fruit washer: classified into fruit surfing washing machine and brush spray washing machine. Used for clean and roughly selection of fruits and vegetables, especially those hard to clean, like carrots.

- Fruit crusher: classified into hammer crusher and squirrel-cage crusher. Used for primary crusher of fruits and vegetable.

- Preheat machine: used to soften raw materials, eliminate enzyme, and protect color.

- Fruit pulping machine: used to pulp kernel fruits and extract juice or puree, such as mango, peach, strawberry, apricot, tomato, raspberry, and kiwi fruit.

- Juice extractor: includes spiral juice extractor and belt juice extractor. Applies to kernel fruits like apple, pear and mango, with high juice yield rate.

- Vacuum concentrator: includes climbing film and falling film juice concentrating pan, external circulating fruit jam concentration machinery.

- Tube-in-tube pipe sterilizer: use steam, hot and cold water as heat transfer agent, applies to raw materials with medium and low viscosity.

- Aseptic filling machine: equipped with an asepsis room. Accomplish the process of opening cover, canning, metering and sealing.

6. Set up and Cost of Starting Fruit Juice Processing Unit

- The minimum area required for the fruit juice processing business is around 1000 sq ft.

- The cost will obviously depend on the size and the production capacity of the unit. One can start a Fruit Juice processing Plant with as low as Rs 3,00,000 to 15,00,000.

7. Fruit Juice Manufacturing Process

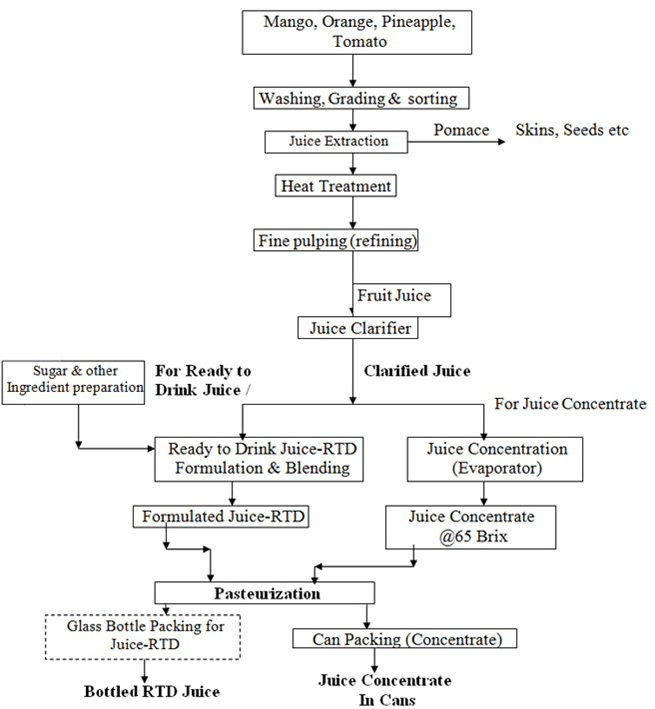

The fruit juice manufacturing process starts with sound fruit, freshly harvested from the field or taken from refrigerated or frozen storage. Thorough washing is usually necessary to remove dirt and foreign objects and may be followed by a sanitation step to decrease the load of contaminants. Sorting to remove decayed and moldy fruit is necessary to make sure that the final juice will not have a high microbial load, undesirable flavors, or mycotoxin contamination.

For most fruits, preparation steps such as pitting and grinding is required prior to juice extraction. Heating and addition of enzymes might also be included before the mash is transferred to the extraction stage. Juice extraction can be performed by pressing or by enzymatic treatment followed by decanting. The extracted juice will then be treated according to the characteristics of the final product.

For cloudy juices, further clarification might not be necessary or may involve a coarse filtration or a controlled centrifugation to remove large insoluble particles. For clear juices, complete de-pectinization by addition of enzymes, fine filtration, or high speed centrifugation is required to achieve visual clarity.

The next step is usually a heat treatment or equivalent non-thermal process to achieve a safe and stable juice and final packaging if single-strength juice is being produced. For a concentrate, the juice is fed to an evaporator to remove water until the desired concentration level is obtained. Other processes used for water removal include reverse osmosis and freeze concentration, which are best suited for heat-sensitive juices. The concentrate is then ready for final processing, packaging, and storage.

Any fruit juice manufacturing plant includes a set of procedures though it differs for some types of processes.

-

- Fruit selection and preparation

- Juice extraction

- Straining and filtration

- Cooling

- Packing and storage.

8. Promote your Products

- The market you products to retailers, such as convenience stores, restaurants, supermarkets, petrol station, grocery store chain, parks, etc. Also, you can find agencies in charge of the distribution and sales in certain areas. If you only sell concentrated juice to juice drink manufactures, you’d better establish long-term cooperation with several major manufacturers.

- Brand your products through website, TV, media, outdoor advertising, event planning, and trade exhibition. Design appealing packages and new tastes to attract customers.

- Quality and attractive packaging play an important role in product promotion. Because it helps to create good visual aspects. So a durable and attractive packaging is a must for this business. Additionally, the overall success of this business depends on the wide distribution network. However, try to tap the local market first.

- Create a website and go online. And then concentrate on expanding. Additionally, focus on institutional selling. In any sort of consumer food product item, outdoor advertising and television add to play a big role.

- However, ensuring the availability of your product in every possible retail location is the most crucial aspect for a successful fruit juice manufacturing company.

Explore

Related Products