What is Paneer?

- Paneer is one of the most popular traditional milk products. This is produced by processing of milk by heating and acid coagulation. It is consumed extensively all over the country.

- Paneer is a fresh cheese. It is an unaged, acid-set, non-melting farmer cheese or curd cheese. Generally, paneer is famous in almost Asia Pacific countries like India, Bangladesh, Pakistan, Afghanistan, etc. However, the production of paneer is now spreading throughout the world.

- In the Indian market, we find paneer in two different categories. One is for fresh selling and another is packaged paneer. However, fresh paneer has a small shelf life compared to packaged paneer. Any individual can start a paneer manufacturing unit with a moderate startup capital investment. Also, the manufacturing process is simple. Paneer production business is a very lucrative and entrepreneurs can easily be associated with this line of dairy product business.

Is Paneer Making Business Profitable?

- The paneer making business is considered as the profitable and lucrative. It falls under the milk processing technique. Paneer is widely consumed by some Asian countries like, India, Pakistan, Bangladesh etc. Of late many Western countries other than Asian countries are getting involved in paneer production.

- Paneer is widely consumed by the people of India more precisely by the people of South India. The reason behind this popularity is maximum of the population is vegetarian and they find paneer as the best replacement of fish and meat. However, the non-vegetarians also consume paneer and this is why it is available everywhere in the country. You can get paneer in supermarkets, grocery stores, departmental stores, etc. According to the surveys, the hotel and restaurant industries are the largest consumer of paneer.

- The brand like Amul and Nestle are acquiring 65% of the paneer market. The consumption of paneer in India is increasing up to 30% per year. Therefore, startup business on paneer production can be lucrative to the new businessman. The one who is already in dairy business can easily start a paneer production business.

Eight steps to start a profitable Paneer Production Business

1. Create a Business Plan

A business plan is a key to success for any business. A well-crafted business plan is required to speak of the operational process of the business in a profitable manner. The three steps in a business plan can include – market study, product & business model and create a project report (including finance and budget).

2. Choose a Location for Paneer Processing Factory

Find a location, where distribution cost is low. The location should be nearer to the suppliers who will supply raw materials to your plant. It also should not be too far from the immediate market where you will be supplying finished goods.

3. Name your Paneer Processing Business

Select a name that people can relate to your Paneer processing company. Do not forget to check the availability of a similar domain name to the company name. This helps you in creating a website similar to the company name.

4. Make the Business Legally Compliant

- Regardless of the size of the business every entrepreneur requires to register for the business. You are required to register for paneer production business. The registration will provide insurance coverage to your business. Apart from that, you need to register the company’s name for legitimate validation. To get your business registered you need to follow the below-stated steps.

- To start a business first you require a business that you have to arrange it from the municipal corporation. The local municipality also provides space for setting up the start-up business.

- When it comes to the food product you need to register it under FSSAI. On the other hand, according to the PFA Act (2010), it is required to follow specific condition regarding paneer production. For instance, the moisture quantity will be no more than 70% and the fat content should not exceed more than 50%.

- You need to go through a quality detection test. Only after passing the test you will get the MSME registration. The entire process can be done online.

- As a start-up business you need to apply for BIS certificate.

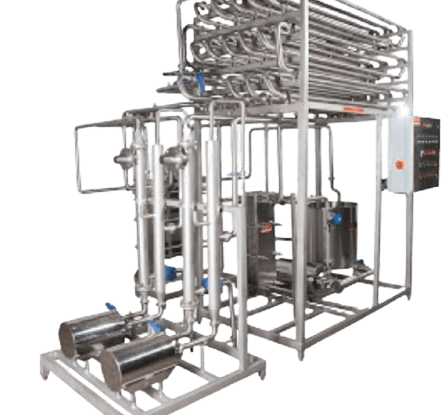

5. Machine & Equipment for Paneer Processing

The Paneer Processing Plant is basically composed of :

- Milk Reception Section

- Paneer Vat

- Paneer Hoops

- Paneer Press (Pneumatically operated)

- Paneer Cutting Machine

- Vacuum Sealing Machine

- Paneer Cold Room.

6. Cost of Starting Paneer Processing Unit

It is without saying, the cost and investment will mainly depend on the scale of business and production output. The cost of a paneer manufacturing plant with a capacity of 500ltrs/her is around Rs. 7 Lacs. You also need other machinery and equipment for making commercial paneer production. Furthermore, an area of a minimum of 2000 sq. ft will be needed to run the paneer manufacturing unit.

Overall, the cost of starting a paneer manufacturing plant business will be in the range of Rs. 20 Lacs to Rs 25 Lacs.

7. Paneer Plant Set Up Space and Production Process

- In order to start a small business you require a proper space. To establish a paneer production unit at a small scale, you need arrange a place with a minimum area of 1000 square feet. Along with this, you need an area for processing, packing, store room, an area to store the finished product, and an area for transport. To start the business few necessary resources are crucial, for example, water and electricity. Therefore, it is clear that preparing a draft of project report is much needed before establishing the business.

- For paneer manufacturing process, first of all, you would need to process the milk for skimming in a cream separator. Then the skimmed milk is heated up to around 60 degrees centigrade. Then afterwards, a few drops of lime extract or citric acid is added to split the milk. After that, the coagulated mass is filtered through a muslin cloth and filter pressed when the cake is obtained. Finally, the paneer is sliced manually to the desired weights, packed in wax paper, and stored under refrigerated conditions.

8. Promote your Products

Generally, the long-term success of FMCG products depends on the successful distribution network. In addition, you will need to concentrate on tying up with the malls, supermarkets, and retail chains. Overall branding and advertising are a must in the and paneer manufacturing business.

* Packaging of Paneer

Freshly made paneer cannot last more than three days. Therefore, it requires special attention. During the packaging it is delicately handled so that it can last a little longer. The whole idea behind packaging is to increase the life of the product. The packaging can be done in various ways. You can pack the pieces into polythene. In case of industrial production vacuum packaging machine is used. The packaging is finished with the heat sealing and lastly, packed paneer is kept in the freezer.

Make sure that you choose the excellent quality of packaging products which will tend to increase the life of the product. You have to use either heat seal or vacuum packaging for excellent results.

Explore

Related Products